DuPont™ Liveo™

Enabling smarter healthcare and positive patient solutions

Building on a strong foundation of expertise and innovation brought by Dow Corning’s healthcare silicone solutions, Liveo™ performance materials impact a broad range of advanced healthcare applications in three key healthcare markets ̶ biopharmaceutical processing, pharmaceutical solutions and medical devices.

DuPont™ Liveo™ Healthcare Solutions expands its capabilities and manufacturing capacity to help meet the healthcare industry’s rapid expansion.

Inspired by the terms “live” and “to be alive,” Liveo™ reflects our drive to create innovative next-generation solutions that can help patients live life to the fullest. Built on a strong foundation and unmatched heritage from Dow Corning, Liveo™ medical-grade solutions provide safety and patient benefits and help customers address a wide range of healthcare challenges.

Liveo™ is focused on customer needs, investing, innovating, and expanding our global manufacturing capabilities and our product portfolio to respond to increased healthcare market demands – for today and for the future.

The broad Liveo™ product portfolio of performance materials is supported by our legendary expertise, transformational science and competencies in connected solutions.

Looking for certifications and regulatory documentation? Please visit the Resource Center for any publicly available documentation or reach out to your commercial contact for any customer-specific documentation.

Advantages

Outstanding quality

Backed by science and rigorously tested, our high-performance healthcare solutions enhance the lives of millions.

Key collaboration

We work with our customers - sharing ideas and insight - as partners to deliver innovative, targeted solutions.

Regulatory compliance

Our regulatory adherence and quality processes strengthen confidence in our solutions along the healthcare value chain.

Next-gen innovation

We are at the forefront of strategies, technologies and technical expertise working in concert to develop our next breakthrough innovation.

Essential healthcare innovations that improve lives

From high-quality and easy-to-process medical-grade elastomers to adhesives and parts, Liveo™ offers solutions for medical device applications.

With exacting purity, Liveo™ products advance single-use solutions for end-to-end purity, reliability and security.

Providing pharmaceutical innovations to advance healthcare, Liveo™ chemistry plays a vital role in patient wellness.

Liveo™ brand product families

Liveo™ brand silicones have demonstrated their safety and patient benefits in a wide range of healthcare applications. These high-quality, reliable and innovative materials include:

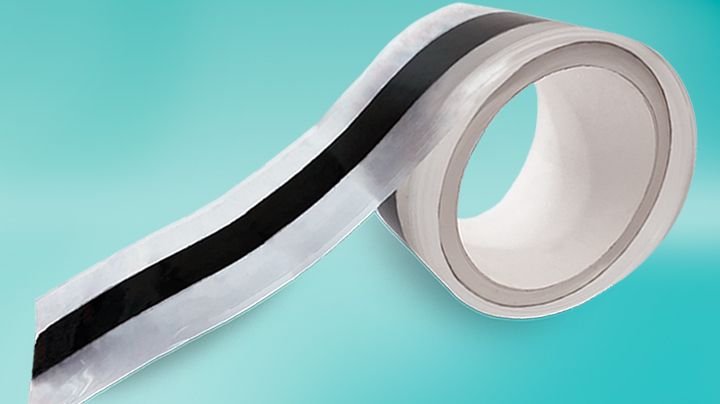

Pressure sensitive adhesives (PSAs) and soft skin adhesives (SSAs) for wearable monitoring devices, wound care products, medical device attachments and more.

Pressure sensitive adhesives (PSAs) in solvents specifically designed to adhere transdermal drug delivery systems to the skin.

Elastomers for fabrication of medical, surgical and diagnostic devices and components.

Thoroughly tested, fully traceable and comprehensively documented tubing to reduce the risk of contamination.

Custom-molded silicone assemblies designed for ultra-pure transfer applications in biopharmaceutical and pharmaceutical manufacturing processes.

High-purity overmolded assemblies to seal glass and plastic bottles and containers used in biological drug production.

Fluids, emulsions, and dispersions used in medical device lubrication when parenteral or as process aid.

Excipients that allow you to formulate innovative solutions for the efficient delivery of your active pharmaceutical ingredients (API) in topical forms like creams, lotions, gels, ointments, sprays or sticks.

Topical formulations that address today’s healthcare challenges, provide efficacious drug delivery and encourage patient compliance.

Compounds and emulsions to reduce and control foam across a variety of pharmaceutical and biopharmaceutical applications.

Markets

Case studies & articles

Discover Liveo™ silicone healthcare solutions in action