New Kapton® Polyimide Film  Addresses the Impact of Higher Switching Frequency and Faster Voltage Rise on Motor Insulation

Addresses the Impact of Higher Switching Frequency and Faster Voltage Rise on Motor Insulation

November 19, 2020

A recently completed research study conducted by a key customer shows that a new Kapton® polyimide film—when used to insulate the conductors found in high-performance traction motors for the e-mobility market—provides an eight-fold improvement over standard polyimide films for insulating the conductors. This new product, Kapton® ECRC, is part of the new corona-resistant wire insulation offerings from the Interconnect Solutions (ICS) business, part of Electronics & Imaging.

The research effort was funded by the Swedish Energy Agency and led by ABB Sweden, a global leader in the design and production of electrical drives, generators, and integrated digital powertrain solutions. Chalmers University of Technology in Sweden also participated in the research and evaluation project.

The Swedish study evaluated the impact of increased electrical stresses caused by high switching frequency converters providing signals with a faster rise of voltage with respect to time (dv/dt) on the conductor insulation materials used in today’s advanced traction motors. The conductor insulation was also exposed, in test conditions, to high temperatures (150 to 180°C) and high voltages (3.0 and 3.5 kV).

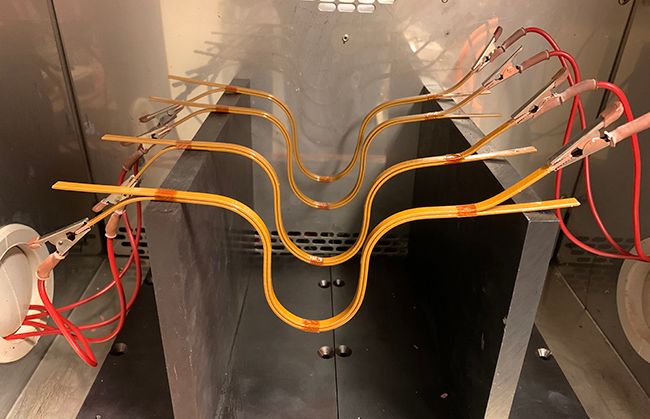

This photo shows the testing set-up at Chalmers University of Technology in Sweden where ABB studied the effects of increased electrical stresses caused by high switching frequency converters on conductors insulated with DuPont™ Kapton® polyimide film. (photo courtesy of Chalmers University, Sweden)

According to Dr. Shafigh Nategh, research project leader for ABB, the Kapton® ECRC film outperformed all other candidate materials tested. “We concluded that Kapton® ECRC polyimide films may be considered as proper candidates for high-switching frequency traction motors designed and produced for the electrification market,” said Dr. Nategh. “The comparison between non-corona resistant Kapton® FN and the 25 percent thinner corona resistant Kapton® ECRC materials showed that Kapton® ECRC film increased the average life-time of the insulation by about 8 times.”

“These research findings help us better understand the impact of increased switching frequency from inverters on a new generation of corona-resistant Kapton® polyimide film wire insulation,” said Shawn Filliben, Technical Service Senior Consultant for DuPont™ Kapton® films. “This new technology will enable designers to have higher performing thin insulation to compete with historical enamel solutions, and a thinner insulation material will provide an additional degree of design freedom for those looking to create smaller, more reliable motors.”

For more than 30 years, DuPont™ Kapton® polyimide films have been successfully insulating conductors to meet evolving needs in a variety of industries, including aerospace and rail applications. Kapton® films have demonstrated improved service and operational efficiencies as compared to conventional insulation materials.

Related Information

DuPont brings a deep understanding of high-performing materials to enhance printed circuit board materials reliability for flexible and rigid boards.

DuPont™ Kapton® polyimide films withstand extreme temperature and vibration with a unique combination of electrical, thermal, chemical and mechanical properties.

We’re here to help.

We love to talk about how our electronics solutions can build business, commercialize products,

and solve the challenges of our time.