Inkjet printing for eco-friendly PCB etch processes

August 11, 2016

As printed circuit boards (PCBs) become increasingly more complex and tolerances become smaller, manufacturers have to keep pace by improving process capability. Likewise, price pressures have driven elimination of costs from operations through improvements in efficiency and yield. Engineers have long dreamed of directly writing images to boards as a means of eliminating process steps. These drivers, along with the needs of new markets like photovoltaics, LCDs, printed and plastic electronics, have brought processes like inkjet printing to the forefront.

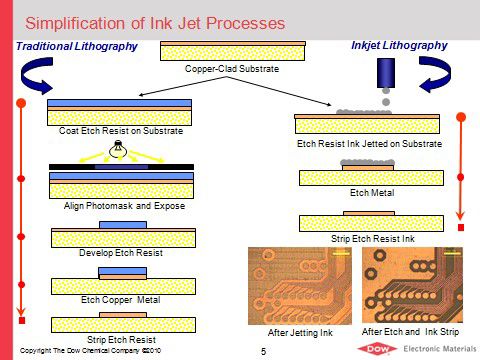

The promise of inkjet printing is that it is an additive process, greatly reducing material waste as compared to a traditional lithographic process. The digital nature of the technique allows for direct CAD-to-board processing and in-process image compensation. Photomasks are eliminated along with their related process costs and storage requirements. Inkjet printing is also a non-contact method, so is an ideal technique for fragile and/or thin substrates.

Figure 1 : Inkjet Printing for PCB Etch Processes

In addition to elimination of the photomask generation process, the downstream developing process step is also eliminated, which can save on water, energy, waste treatment processes and maintenance down time. Overall, it is a much more environmentally friendly process than traditional approaches. Inkjet imaging is inherently better environmentally than traditional lithographic techniques, in terms of both materials and processes. For example, in a standard dry-film process used for lithography, the resist itself must be produced by casting the lacquer onto the polyester sheet from solvent carriers like acetone, alcohol or MEK. Dry film lacquer is 30% to 50% solids, meaning 50% to 70% is volatile organic content (VOC) that must be evaporated and treated, usually by burning. Even liquid photo-imageable (LPI) resists contain up to 65% solvents.

Inkjet inks, like Dow Electronic Solution’s Lithojet™ 223 inks, for example, are 100% solids, so no VOCs are evolved during manufacture or use. When a dry film is used as an etch resist, approximately 50% or more of the material is developed away as waste. By contrast, inkjet ink is deposited only where it is needed, so the waste is minimal. In addition, the typical thickness of an applied inkjet ink is 15 to 30 microns, compared to 30 to 75 microns for dry film. Based on these numbers, an inkjet process uses only about 30% of the material of a dry film process, meaning there is 70% less material to waste treat. Dry film processes also require photomask generation and resist development, along with the associated water, chemical and energy use, as well as labor. Additional packaging such as boxes, plastic cores, end supports and cover sheets further add to the total material bill of dry film processes.

Most inkjet etch resist ink products for PCB manufacturing are either phase-change wax inks or UV-curable liquid inks, but have drawbacks: they are either too soft or spread too much respectively. Dow’s Lithojet™ 223 ink uses a different approach in ink design, combining the desirable attributes of both ink types. Although not truly a phase-change reaction, the cooling of the ink sets it in place within a short time after printing, allowing the ink to be pinned with very little spreading, regardless of surface conditions. The height and width of the ink deposit is dependent on the ink characteristics, substrate characteristics and print head capabilities (primarily drop size). Under the proper jetting conditions, these inks are capable of producing 75 um or less features. The inks are also very hard, tack free and chemically resistant after UV curing. Hardness measurements are typically 3H to 4H and as a result will be more difficult to damage than most liquid or dry film photoresist. Chemical resistance is also very good to acid and alkali based etchants.

Want to learn more about inkjet printing for advanced packaging applications? Our Lithojet™ experts will be available to meet with customers at PCB West, which takes place Sept. 13-15, 2016 at the Santa Clara Convention Center.

Related Information

Nickel-free electroless Cu plating chemistry enables fine-pattern plating in advanced IC substrates.

How to get excellent electrical and mechanical connections between advanced PCBs and IC packages.

A UV-curable acrylic hybird ink ideal for quick-turn and prototype board fabrications, eliminates dry film and photo-mask for PWB innerlayer fabrication

We’re here to help.

We love to talk about how our electronics solutions can build business, commercialize products,

and solve the challenges of our time.