Addressing the evolving demands of industrial water and specialty processing

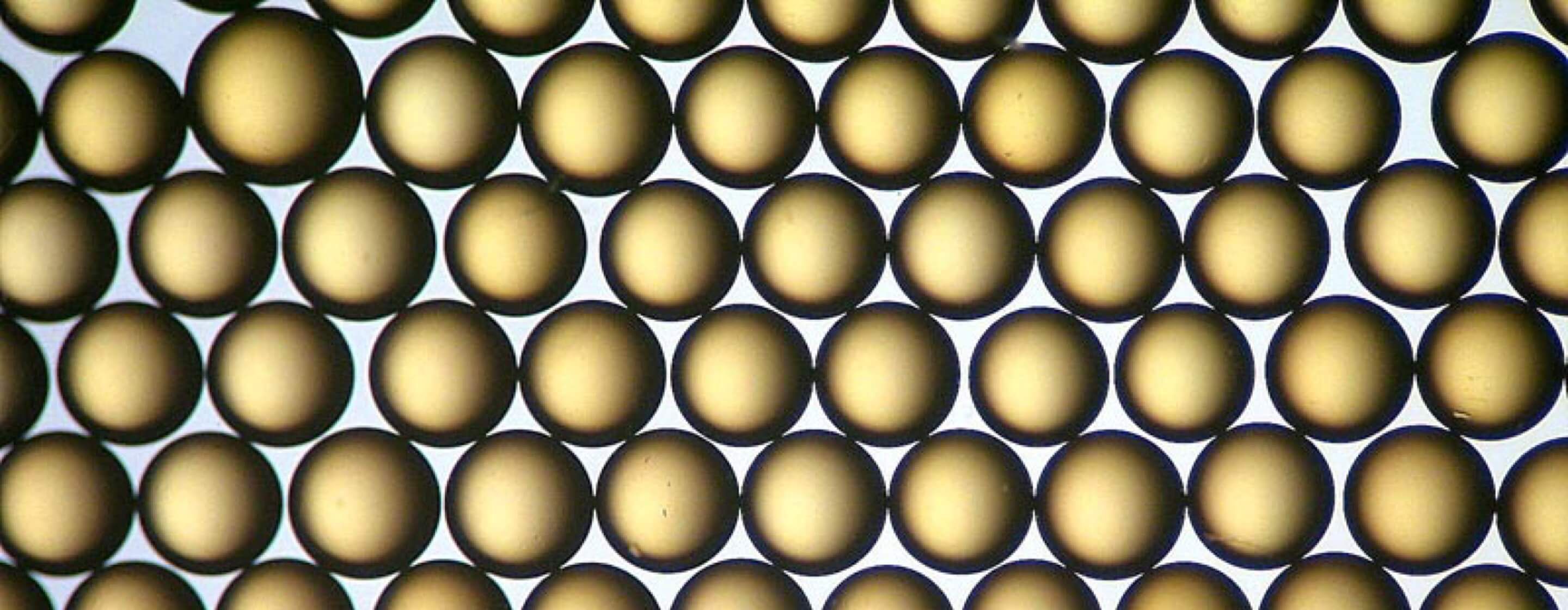

Backed by 80 years of application development and years of extensive performance testing, our Amber series of resins are the most trusted ion exchange resin trade names in the industry. Our innovations in ion exchange (IX) water treatment and separation have driven key improvements in reliability, productivity, efficiency, and safety.

The Amber series of resins are available in a wide range of chemical compositions and polymer structures. From providing exceptional technical service to the highest quality product performance, we can help you solve your water management and separation challenges for optimal plant productivity in industries and markets including industrial water, food and beverage, bioprocessing, power generation, chemical processing, catalysis, mining, and drinking water.

Related industries

The products in our Amber series were developed to keep facilities operating at peak levels through highly effective water separation and purification. Learn more about the industries and markets that can benefit from ion exchange water treatment technology.

We enable complicated separations for drug synthesis resulting in better outcomes for patients and life science companies.

As a global market leader for catalyst ion exchange resins, our polymeric catalysts are used throughout the world in order to enable the production of critical products such as BPA, fuel ethers, esters, and phenols.

We offer chemical processing solutions including feed stock purification, brine and acid purification, as well as chlorine-based and metal-based hydroxide solutions.

Every day we help feed the world through farm to table processing solutions focused on healthier foods and protein-based diets.

Our technologies and solutions are designed to help you overcome water challenges to produce your desired quantity and quality of industrial utility water.

We develop best-in-class technologies, accompanied by an advanced product portfolio of solutions, to address your crucial wastewater challenges.

We enable the production of some of today’s most popular technologies by facilitating ultrapure water and effective water reuse.

We facilitate the sustainable recovery of valuable raw materials through specialty separation technologies.

We help ensure a steady flow of clean, safe drinking water into local communities with our water-treatment solutions.

We help energy companies improve operational efficiency with specialized water treatment and wastewater reuse.

We facilitate pharmaceutical formulations and advanced drug delivery through our offering of excipients and Active Pharmaceutical Ingredients (APIs).

A complete portfolio of trusted products and breakthrough technologies

Expertise, partnership, and product innovation

DuPont Water Solutions has been a partner to the water-treatment industry and plant owners for decades, with a history of application development, technical service, and product innovations in ion exchange technologies that contribute to measurable improvements in reliability, productivity, efficiency, and safety. Backed by extensive performance testing and world-class application experience, the Amber series ion exchange resin portfolio for industrial water will help you maximize the performance of our products in your hands and provide the quality and reliability you need on a daily basis.

Our recommended ion exchange products for industrial water treatment, including producing softened water or demineralized water, include:

- DuPont™ AmberLite™ HPR weak and strong acid cation and weak and strong base anion exchange resins.

- DuPont™ AmberLite™ IRC weak and strong acid cation exchange resins.

- DuPont™ AmberLite™ IRA weak and strong base anion exchange resins.

- DuPont™ AmberLite™ SCAV organic scavenging resins.

- DuPont™ AmberLite™ MB premixed strong acid cation and strong base anion exchange resins.

Extracting value and enhancing quality and productivity

Whatever the complexity of your manufacturing processes, our industry-leading ion exchange products can help beverages and foods look and taste better, products achieve greater consistency, and plants run more productively.

For beverages

Our ion exchange products can play a critical role in meeting consumers’ demands for quality, value, and consistency of beverages, including their clarity, taste, and nutritional value. Companies worldwide work with us so they can provide their customers with the beverages they’ve come to love and count on. Our products are used in the following applications:

- Citrus debittering

- Juice deacidification

- Juice decolorization

- Protein haze stabilization

Our recommended ion exchange products for beverage manufacturing include:

- AmberLite™ FPX macroreticular adsorbent resins.

- AmberLite™ FPA anion exchange resins.

- AmberLite™ FPC cation exchange resins.

- AmberLite™ Optipore™ SD2 macroreticular adsorbent resins.

For dairy

Ion exchange resins, combined with membrane technologies, are used to purify whey — a byproduct of the production of cheese — by removing mineral salts. Weak and strong acid cation exchangers and weak base anion exchangers are used for this purpose and the demineralized whey can then be used in various food applications, or to recover proteins or lactose. Eventually lactose can be hydrolyzed to glucose and galactose, which can be separated on a chromatographic ion exchange resin.

Our recommended ion exchange products for dairy processing include:

- AmberLite™ FPA anion exchange resins.

- AmberLite™ FPC cation exchange resins.

For sweeteners

Our ion exchange resins for corn and starch processing are used in the following applications:

- Deashing and mixed bed polishing

- Chromatography

- Decolorization

- Enzymatic immobilization

Our ion exchange resins for beet sugar refining are used in the following applications:

- Softening

- Chromatography

Our ion exchange resins for cane sugar processing are used in the following applications:

- Decolorization

Our recommended ion exchange products for sweetener production include:

- AmberLite™ anion and cation exchange resins.

- AmberLite™ PFX adsorbent resins.

- AmberLite™ FPA anion exchange resins.

- AmberLite™ FPC cation exchange resins.

Optimizing performance for nuclear and fossil power plants

Our world-class ion exchange (IX) resins are part of the integrated solutions we bring to nuclear and fossil power plants seeking technologies that treat water more efficiently and effectively. In both nuclear and fossil fuel power plants, ion exchange resins can efficiently remove ionic impurities, producing softened water or partially or fully demineralized water—up to ultrapure water quality. IX resins can be highly specialized to remove a narrow or wide range of contaminants.

For nuclear power plants

Our ion exchange resins, particularly our nuclear-grade ion exchange resins, are trusted in nuclear power plants worldwide for specific applications.

For boiling water reactors, applications include:

- Make-up water treatment

- Condensate polishing

- Radioactive waste, spent fuel pool, and reactorcoolant purification

- Stator cooling water contaminant removal

- Cooling tower blowdown

For pressurized water reactors, applications include:

- Make-up water treatment

- Condensate polishing

- Primary and chemical volume control system (CVCS) water treatment

- Radioactive waste, spent fuel pool, and reactor coolant purification

- Steam generation blowdown

- Stator cooling water contaminant removal

- Cooling tower blowdown

Our recommended ion exchange products for nuclear power plants include:

- DuPont™ AmberLite™ IRN nuclear-grade strong acid cation and strong base anion exchange resins.

- DuPont™ AmberLite™ HPR weak and strong acid cation and weak and strong base anion exchange resins.

- DuPont™ AmberLite™ IRC weak and strong acid cation exchange resins.

- DuPont™AmberLite™ IRA weak and strong base anion e xchange resins.

- DuPont™ AmberLite™ SCAV organic scavenging resins.

- DuPont™ AmberLite™ MB premixed strong acid cation and strong base anion exchange resins.

For fossil power plants

Our ion exchange resins, chosen globally for use in fossil power plants, are tailored for specific fossil power applications, including:

- Make-up water treatment

- Condensate polishing

- Stator cooling water contaminant removal

- Flue gas desulfurization (FGD)

- Steam generator blowdown

- Minimal liquid discharge (MLD)

Our recommended ion exchange products for fossil power plants include:

- DuPont™ AmberLite™ HPR weak and strong acid cation and weak and strong base anion exchange resins.

- DuPont™ AmberLite™ IRC weak and strong acid cation exchange resins.

- DuPont™AmberLite™ IRA weak and strong base anion exchange resins.

- DuPont™ AmberLite™ SCAV organic scavenging resins.

- DuPont™ AmberLite™ MB premixed strong acid cation and strong base anion exchange resins.

Improving selectivity and activity

For over 50 years, we have used our expertise in catalyst technologies to support the chemical and petrochemical industries. Our team has refined the Amber series of ion exchange (IX) resins to enable the purification and recovery of some of the most commercially important products, setting the industry standard for quality and performance.

Our portfolio includes polymeric catalysts whose polymer morphology and porosity can be manipulated to control transport properties to optimize conversion and selectivity. Amber catalysts are easy to use while offering low corrosivity to equipment and enabling the consistent production of high purity products.

From synthesizing alkylphenols to silane disproportionation, our ion exchange products are designed specifically for these applications:

- Alkylation

- Base catalysis

- Condensation

- Dimerization

- Esterification

- Etherification

- Hydrogenation (MIBK)

- Olefin hydration

Our recommended ion exchange products for catalysis include:

Bioprocessing excellence and expertise

As a global market leader in separation and purification solutions, DuPont Water Solutions has an extensive portfolio of products that addresses the specific conditions and requirements of the bioprocessing industry.

The Amber series of reverse phase, adsorbent, and ion exchange resins have been developed for the most complex bioprocessing applications, enabling manufacturers to achieve their desired levels of purity, yield, and throughput for both traditional and emerging therapeutics.

From the purification of crude oligos to detergent removal, our products can be used for the following applications:

- Capture and purification of biomolecules

- Antimicrobial Removal Devices (ARDs)

- Purification of natural extracts

- Enzyme immobilization

- Plasma detoxification

Our recommended ion exchange brands for bioprocessing include:

Production of pharma excipients

Our internationally renowned ion exchange resins have a long history of safe use as pharmaceutical excipients and active pharmaceutical ingredients (APIs), being deployed in a vast array of commercial formulations around the world.

The Amber series of ion exchange resins portfolio has been designed to help solve customer challenges and address some of the most pressing pharmaceutical trends.

From taste-masking to controlling the release of suspension formulations, our products can be used for the following applications:

- Taste-masking

- Tablet disintegration

- Modified release

- Drug stability

- Abuse deterrence

- Solubility enhancement

- Cholestyramine

- Sodium Polystyrene Sulfonate

Our recommended ion exchange products for pharma excipients include:

A community’s potable (i.e. drinking) water can come from diverse sources, including ground water, lakes, rivers, and the ocean. But safe, clean, reliable, and affordable potable water typically requires treatment before it can be of use to residents.

Ion exchange resins are remarkably efficient in removing certain impurities from water that is destined for human consumption, and our resins are in use in municipal water treatment plants around the world.

Our ion exchange resins for drinking water purification are used in the following applications:

- Softening

- Demineralization

- Trace contaminant removal

- Odor removal

- Decolorization

- Nitrate removal

Our ion exchange resins for municipal water treatment include:

- DuPont™ AmberLite™ PWA weak and strong base anions.

- DuPont™ AmberLite™ PWC weak and strong base anions.

- DuPont™ AmberLite™ SCAV organic scavenging resins.

- DuPont™ AmberLite™ HPR1100 strong acid cation exchange resins.

- DuPont™ AmberLite™ cation and anion exchange resins.

-

Industrial Water Treatment

Expertise, partnership, and product innovation

DuPont Water Solutions has been a partner to the water-treatment industry and plant owners for decades, with a history of application development, technical service, and product innovations in ion exchange technologies that contribute to measurable improvements in reliability, productivity, efficiency, and safety. Backed by extensive performance testing and world-class application experience, the Amber series ion exchange resin portfolio for industrial water will help you maximize the performance of our products in your hands and provide the quality and reliability you need on a daily basis.

Our recommended ion exchange products for industrial water treatment, including producing softened water or demineralized water, include:

- DuPont™ AmberLite™ HPR weak and strong acid cation and weak and strong base anion exchange resins.

- DuPont™ AmberLite™ IRC weak and strong acid cation exchange resins.

- DuPont™ AmberLite™ IRA weak and strong base anion exchange resins.

- DuPont™ AmberLite™ SCAV organic scavenging resins.

- DuPont™ AmberLite™ MB premixed strong acid cation and strong base anion exchange resins.

-

Food and Beverage

Extracting value and enhancing quality and productivity

Whatever the complexity of your manufacturing processes, our industry-leading ion exchange products can help beverages and foods look and taste better, products achieve greater consistency, and plants run more productively.

For beverages

Our ion exchange products can play a critical role in meeting consumers’ demands for quality, value, and consistency of beverages, including their clarity, taste, and nutritional value. Companies worldwide work with us so they can provide their customers with the beverages they’ve come to love and count on. Our products are used in the following applications:

- Citrus debittering

- Juice deacidification

- Juice decolorization

- Protein haze stabilization

Our recommended ion exchange products for beverage manufacturing include:

- AmberLite™ FPX macroreticular adsorbent resins.

- AmberLite™ FPA anion exchange resins.

- AmberLite™ FPC cation exchange resins.

- AmberLite™ Optipore™ SD2 macroreticular adsorbent resins.

For dairy

Ion exchange resins, combined with membrane technologies, are used to purify whey — a byproduct of the production of cheese — by removing mineral salts. Weak and strong acid cation exchangers and weak base anion exchangers are used for this purpose and the demineralized whey can then be used in various food applications, or to recover proteins or lactose. Eventually lactose can be hydrolyzed to glucose and galactose, which can be separated on a chromatographic ion exchange resin.

Our recommended ion exchange products for dairy processing include:

- AmberLite™ FPA anion exchange resins.

- AmberLite™ FPC cation exchange resins.

For sweeteners

Our ion exchange resins for corn and starch processing are used in the following applications:

- Deashing and mixed bed polishing

- Chromatography

- Decolorization

- Enzymatic immobilization

Our ion exchange resins for beet sugar refining are used in the following applications:

- Softening

- Chromatography

Our ion exchange resins for cane sugar processing are used in the following applications:

- Decolorization

Our recommended ion exchange products for sweetener production include:

- AmberLite™ anion and cation exchange resins.

- AmberLite™ PFX adsorbent resins.

- AmberLite™ FPA anion exchange resins.

- AmberLite™ FPC cation exchange resins.

-

Power Generation

Optimizing performance for nuclear and fossil power plants

Our world-class ion exchange (IX) resins are part of the integrated solutions we bring to nuclear and fossil power plants seeking technologies that treat water more efficiently and effectively. In both nuclear and fossil fuel power plants, ion exchange resins can efficiently remove ionic impurities, producing softened water or partially or fully demineralized water—up to ultrapure water quality. IX resins can be highly specialized to remove a narrow or wide range of contaminants.

For nuclear power plants

Our ion exchange resins, particularly our nuclear-grade ion exchange resins, are trusted in nuclear power plants worldwide for specific applications.

For boiling water reactors, applications include:

- Make-up water treatment

- Condensate polishing

- Radioactive waste, spent fuel pool, and reactorcoolant purification

- Stator cooling water contaminant removal

- Cooling tower blowdown

For pressurized water reactors, applications include:

- Make-up water treatment

- Condensate polishing

- Primary and chemical volume control system (CVCS) water treatment

- Radioactive waste, spent fuel pool, and reactor coolant purification

- Steam generation blowdown

- Stator cooling water contaminant removal

- Cooling tower blowdown

Our recommended ion exchange products for nuclear power plants include:

- DuPont™ AmberLite™ IRN nuclear-grade strong acid cation and strong base anion exchange resins.

- DuPont™ AmberLite™ HPR weak and strong acid cation and weak and strong base anion exchange resins.

- DuPont™ AmberLite™ IRC weak and strong acid cation exchange resins.

- DuPont™AmberLite™ IRA weak and strong base anion e xchange resins.

- DuPont™ AmberLite™ SCAV organic scavenging resins.

- DuPont™ AmberLite™ MB premixed strong acid cation and strong base anion exchange resins.

For fossil power plants

Our ion exchange resins, chosen globally for use in fossil power plants, are tailored for specific fossil power applications, including:

- Make-up water treatment

- Condensate polishing

- Stator cooling water contaminant removal

- Flue gas desulfurization (FGD)

- Steam generator blowdown

- Minimal liquid discharge (MLD)

Our recommended ion exchange products for fossil power plants include:

- DuPont™ AmberLite™ HPR weak and strong acid cation and weak and strong base anion exchange resins.

- DuPont™ AmberLite™ IRC weak and strong acid cation exchange resins.

- DuPont™AmberLite™ IRA weak and strong base anion exchange resins.

- DuPont™ AmberLite™ SCAV organic scavenging resins.

- DuPont™ AmberLite™ MB premixed strong acid cation and strong base anion exchange resins.

-

Catalysis

Improving selectivity and activity

For over 50 years, we have used our expertise in catalyst technologies to support the chemical and petrochemical industries. Our team has refined the Amber series of ion exchange (IX) resins to enable the purification and recovery of some of the most commercially important products, setting the industry standard for quality and performance.

Our portfolio includes polymeric catalysts whose polymer morphology and porosity can be manipulated to control transport properties to optimize conversion and selectivity. Amber catalysts are easy to use while offering low corrosivity to equipment and enabling the consistent production of high purity products.

From synthesizing alkylphenols to silane disproportionation, our ion exchange products are designed specifically for these applications:

- Alkylation

- Base catalysis

- Condensation

- Dimerization

- Esterification

- Etherification

- Hydrogenation (MIBK)

- Olefin hydration

Our recommended ion exchange products for catalysis include:

-

Bioprocessing

Bioprocessing excellence and expertise

As a global market leader in separation and purification solutions, DuPont Water Solutions has an extensive portfolio of products that addresses the specific conditions and requirements of the bioprocessing industry.

The Amber series of reverse phase, adsorbent, and ion exchange resins have been developed for the most complex bioprocessing applications, enabling manufacturers to achieve their desired levels of purity, yield, and throughput for both traditional and emerging therapeutics.

From the purification of crude oligos to detergent removal, our products can be used for the following applications:

- Capture and purification of biomolecules

- Antimicrobial Removal Devices (ARDs)

- Purification of natural extracts

- Enzyme immobilization

- Plasma detoxification

Our recommended ion exchange brands for bioprocessing include:

-

Pharma Excipients

Production of pharma excipients

Our internationally renowned ion exchange resins have a long history of safe use as pharmaceutical excipients and active pharmaceutical ingredients (APIs), being deployed in a vast array of commercial formulations around the world.

The Amber series of ion exchange resins portfolio has been designed to help solve customer challenges and address some of the most pressing pharmaceutical trends.

From taste-masking to controlling the release of suspension formulations, our products can be used for the following applications:

- Taste-masking

- Tablet disintegration

- Modified release

- Drug stability

- Abuse deterrence

- Solubility enhancement

- Cholestyramine

- Sodium Polystyrene Sulfonate

Our recommended ion exchange products for pharma excipients include:

-

Drinking Water

A community’s potable (i.e. drinking) water can come from diverse sources, including ground water, lakes, rivers, and the ocean. But safe, clean, reliable, and affordable potable water typically requires treatment before it can be of use to residents.

Ion exchange resins are remarkably efficient in removing certain impurities from water that is destined for human consumption, and our resins are in use in municipal water treatment plants around the world.

Our ion exchange resins for drinking water purification are used in the following applications:

- Softening

- Demineralization

- Trace contaminant removal

- Odor removal

- Decolorization

- Nitrate removal

Our ion exchange resins for municipal water treatment include:

- DuPont™ AmberLite™ PWA weak and strong base anions.

- DuPont™ AmberLite™ PWC weak and strong base anions.

- DuPont™ AmberLite™ SCAV organic scavenging resins.

- DuPont™ AmberLite™ HPR1100 strong acid cation exchange resins.

- DuPont™ AmberLite™ cation and anion exchange resins.

Effective ion exchange resins for challenging purification and separation processes

DuPont™ AmberChrom™ resins are available in two families of resins based on either a methacrylate or aromatic structure. A variety of particle and pore sizes are offered in each group.

DuPont™ AmberLite™ resin is an insoluble, strongly acidic, sodium form cation exchange resin supplied as a dry powder. It is suitable for use in pharmaceutical applications, both as an active ingredient and as a carrier for basic (cationic) drugs.

DuPont™ AmberLyst™ Ion Exchange Resin is a highly porous, granular, weak base anion exchange resin based on crosslinked phenol-formaldehyde polycondensate. Its ion exchange activity is due almost entirely to tertiary amine groups. Consequently, it exhibits minimal strong base capacity. Regeneration with little more than stoichiometric amounts of alkali is rapid and complete. It has proven more efficient than conventional polystyrene resins in a variety of applications.

DuPont™ AmberSep™ is a resin of macroporous structure. Its polystyrenic matrix, crosslinked with DVB, contains aminophosphonic groups. The chemical nature of these groups is such that they form complexes with metal ions. AmberSep™ may be distinguished from aminodiacetic resins by its specificity for various cations and by the greater stability of the complexes formed with cations of low atomic mass.

DuPont™ AmberSorb™ is used for the removal of organic compounds from liquid or vapor streams in drinking water or chemical processing.

DuPont™ AmberTec™ is a uniform particle size, gel, strong acid cation exchange resin for single bed and mixed bed demineralization applications.

-

AmberChrom™

DuPont™ AmberChrom™ resins are available in two families of resins based on either a methacrylate or aromatic structure. A variety of particle and pore sizes are offered in each group.

-

AmberLite™

DuPont™ AmberLite™ resin is an insoluble, strongly acidic, sodium form cation exchange resin supplied as a dry powder. It is suitable for use in pharmaceutical applications, both as an active ingredient and as a carrier for basic (cationic) drugs.

-

AmberLyst™

DuPont™ AmberLyst™ Ion Exchange Resin is a highly porous, granular, weak base anion exchange resin based on crosslinked phenol-formaldehyde polycondensate. Its ion exchange activity is due almost entirely to tertiary amine groups. Consequently, it exhibits minimal strong base capacity. Regeneration with little more than stoichiometric amounts of alkali is rapid and complete. It has proven more efficient than conventional polystyrene resins in a variety of applications.

-

AmberSep™

DuPont™ AmberSep™ is a resin of macroporous structure. Its polystyrenic matrix, crosslinked with DVB, contains aminophosphonic groups. The chemical nature of these groups is such that they form complexes with metal ions. AmberSep™ may be distinguished from aminodiacetic resins by its specificity for various cations and by the greater stability of the complexes formed with cations of low atomic mass.

-

AmberSorb™

DuPont™ AmberSorb™ is used for the removal of organic compounds from liquid or vapor streams in drinking water or chemical processing.

-

AmberTec™

DuPont™ AmberTec™ is a uniform particle size, gel, strong acid cation exchange resin for single bed and mixed bed demineralization applications.

Find Amber series products

Search for product information for Amber series ion exchange resins, including product data sheets.

Select Application and Product Selection Guides

Refer to these guides to see specific recommendations for industrial and power market water treatment applications.

Power generation water treatment

Fossil Application and Solution Interactive Map

Nuclear Application and Solution Interactive Map

Fossil Power Plant Condensate Polisher

Flue Gas Desulfurization and Ash Pond Cleanup

Pressurized Water Reactor Chemical & Volume Control System (Primary Loop Chemistry)

Pressurized Water Reactor Condensate Polisher

Boiling Water Reactor Condensate Polisher and Reactor Water Clean Up

Related technologies

Our technologies provide industry-leading, long-lasting, and cost-effective solutions. Learn more about the technologies used in Amber series products.

IX uses polymeric resins capable of exchanging ions; applications include softening, bulk demineralization, trace contaminants removal, and condensate water polishing.

Related resources

See what’s possible

Ask how we can help your industry or market with our leading Amber series of ion exchange resins.