Solving wastewater challenges with a more cost-effective approach than Zero Liquid Discharge (ZLD)

Evolving wastewater regulations can create demanding and sometimes costly production challenges. Factors such as the rising price of water and the significant cost of zero liquid discharge (ZLD) can greatly affect your ability to meet production goals. Many facilities are seeking an alternative to ZLD. Not only is it expensive, but it is not necessarily the most environmentally friendly process because of the energy and resources it requires.

DuPont Water Solutions helps to address wastewater regulatory challenges with our minimal liquid discharge (MLD) solution. MLD has the potential to minimize operating costs of achieving high water recovery while reducing the amount of energy required to operate compared to traditional ZLD processes. With the industry’s broadest portfolio of purification and separation technologies, our solutions can provide cost savings, higher recovery, and improved environmental stewardship.

Transforming industrial wastewater treatment with MLD

Improving recovery rate at a fraction of ZLD's cost

Many industrial and municipal plants are turning to a minimal liquid discharge (MLD) approach: a core set of integrated processes based on ultrafiltration (UF), reverse osmosis (RO), nanofiltration (NF), and ion exchange (IX) technologies.

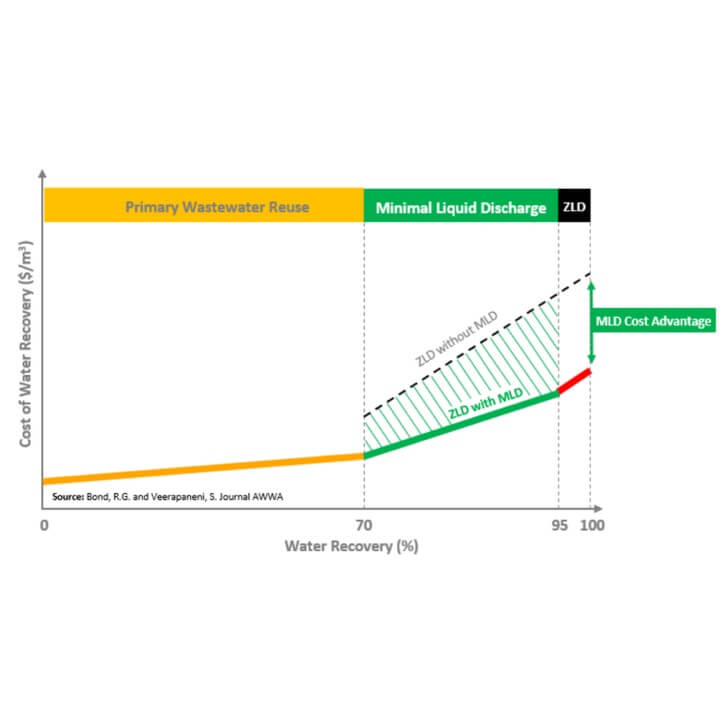

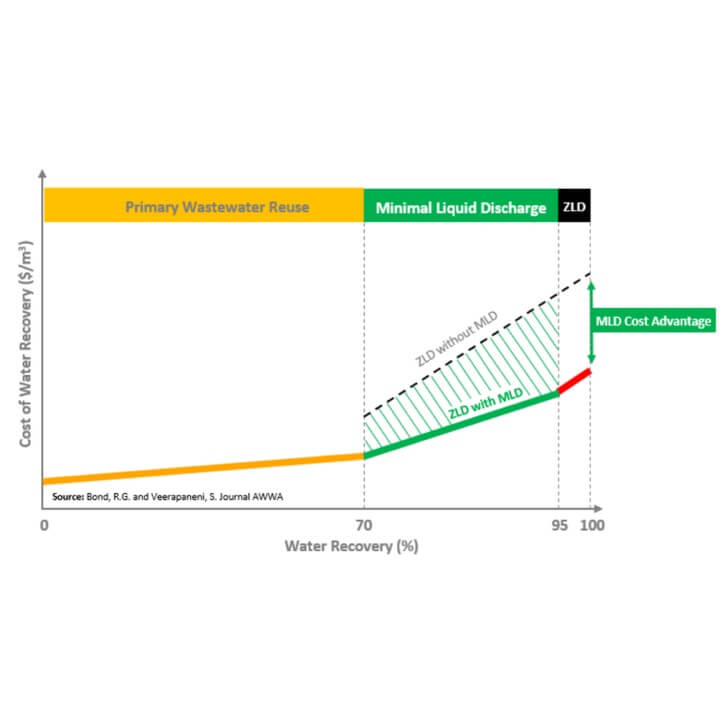

With MLD, the circular water economy can be improved by recovering up to 95 percent liquid discharge for reuse — but at a fraction of ZLD’s costs. The cost of using RO to recover and reuse up to 70 percent of wastewater is competitive with treating local, fresh-water sources, but it leaves behind 30 percent of the water. When water prices are high and/or water availability is limited, recovering more water becomes necessary.

The thermal processes used in ZLD treatment to recover more water often result in higher costs that are not feasible. But, by practicing MLD, up to 95 of the wastewater can be recovered using membranes prior to thermal processing, which significantly lowers the cost of the recovered water and the overall cost of ZLD by up to 60 percent.

Integrating UF, RO, NF, and IX technologies for minimal liquid discharge

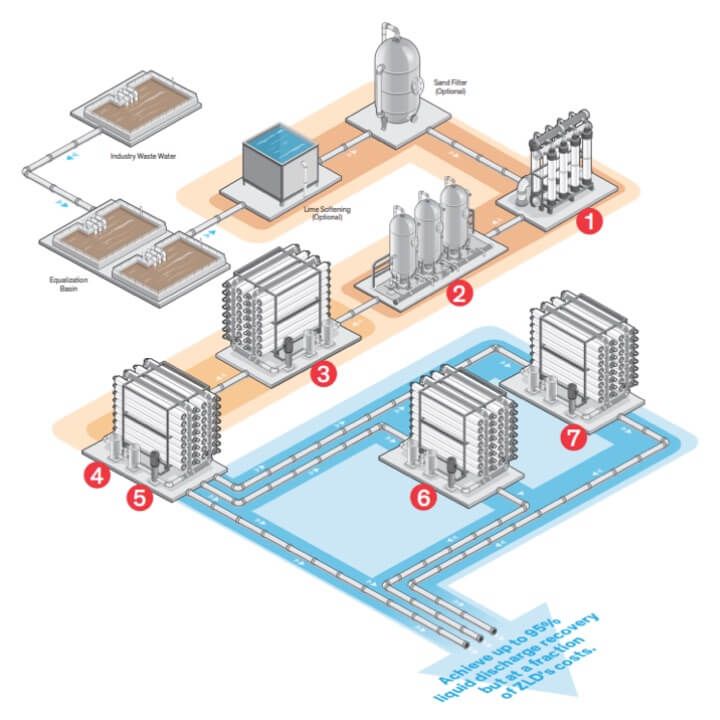

Our minimal liquid discharge products work together within a water treatment system to recover wastewater at low total cost. A typical system set-up may appear like as the following:

- DuPont™ IntegraTec™ XP ultrafiltration modules can minimize the need for pretreatment and reduce backwash volume.

- DuPont™ AmberLite™ IRC83 WAC resins can remove hardness with up to 30 percent more operating capacity.

- FilmTec™ Fortilife™ CR200 RO membranes can reduce cleanings by up to 50%.

- FilmTec™ Fortilife™ XC70 and XC80 RO membranes can recover purified water for reduced brine volume.

- FilmTec™ Fortilife™ XC120 RO membranes can maximize reject concentration at standard RO operating pressures.

- FilmTec™ Fortilife™ UHP RO membranes can minimize brine volume.

- FilmTec™ Fortilife™ NF1000 and NF1000 HP salt separation membranes can purify brines from wastewater streams for salt reuse applications.

Industry-leading minimal liquid discharge technologies

DuPont has developed a broad range of products to help reduce the cost and energy requirements for treating wastewater. FilmTec™ Fortilife™ reverse osmosis elements help customers reduce costly concentrate waste, lower operating expenses, and move toward MLD. Our expertly designed RO elements include FilmTec™ Fortilife™ CR200, CR100, XC70, XC80 and XC120, which are equipped to tackle the fouling challenges of high recovery wastewater reuse operations while operating with in standard RO pressure ranges.

The FilmTec™ Fortilife™ UHP reverse osmosis element goes beyond and maximizes water recovery and reject concentration by expanding operating pressure ranges up to 120 bar.

The FilmTec™ Fortilife™ NF1000 and NF1000 HP elements can be used to further treat wastewater by enabling the recovery of purified brines for reuse purposes and reduce salt waste.

In addition, our DuPont™ AmberLite™ IRC83 ion exchange resins can reduce water hardness and help you achieve up to 30 percent more operating capacity than other weak acid cation resins.

-

Efficiency and Savings

Improving recovery rate at a fraction of ZLD's cost

Many industrial and municipal plants are turning to a minimal liquid discharge (MLD) approach: a core set of integrated processes based on ultrafiltration (UF), reverse osmosis (RO), nanofiltration (NF), and ion exchange (IX) technologies.

With MLD, the circular water economy can be improved by recovering up to 95 percent liquid discharge for reuse — but at a fraction of ZLD’s costs. The cost of using RO to recover and reuse up to 70 percent of wastewater is competitive with treating local, fresh-water sources, but it leaves behind 30 percent of the water. When water prices are high and/or water availability is limited, recovering more water becomes necessary.

The thermal processes used in ZLD treatment to recover more water often result in higher costs that are not feasible. But, by practicing MLD, up to 95 of the wastewater can be recovered using membranes prior to thermal processing, which significantly lowers the cost of the recovered water and the overall cost of ZLD by up to 60 percent.

-

Typical System Setup

Integrating UF, RO, NF, and IX technologies for minimal liquid discharge

Our minimal liquid discharge products work together within a water treatment system to recover wastewater at low total cost. A typical system set-up may appear like as the following:

- DuPont™ IntegraTec™ XP ultrafiltration modules can minimize the need for pretreatment and reduce backwash volume.

- DuPont™ AmberLite™ IRC83 WAC resins can remove hardness with up to 30 percent more operating capacity.

- FilmTec™ Fortilife™ CR200 RO membranes can reduce cleanings by up to 50%.

- FilmTec™ Fortilife™ XC70 and XC80 RO membranes can recover purified water for reduced brine volume.

- FilmTec™ Fortilife™ XC120 RO membranes can maximize reject concentration at standard RO operating pressures.

- FilmTec™ Fortilife™ UHP RO membranes can minimize brine volume.

- FilmTec™ Fortilife™ NF1000 and NF1000 HP salt separation membranes can purify brines from wastewater streams for salt reuse applications.

-

MLD Technologies

Industry-leading minimal liquid discharge technologies

DuPont has developed a broad range of products to help reduce the cost and energy requirements for treating wastewater. FilmTec™ Fortilife™ reverse osmosis elements help customers reduce costly concentrate waste, lower operating expenses, and move toward MLD. Our expertly designed RO elements include FilmTec™ Fortilife™ CR200, CR100, XC70, XC80 and XC120, which are equipped to tackle the fouling challenges of high recovery wastewater reuse operations while operating with in standard RO pressure ranges.

The FilmTec™ Fortilife™ UHP reverse osmosis element goes beyond and maximizes water recovery and reject concentration by expanding operating pressure ranges up to 120 bar.

The FilmTec™ Fortilife™ NF1000 and NF1000 HP elements can be used to further treat wastewater by enabling the recovery of purified brines for reuse purposes and reduce salt waste.

In addition, our DuPont™ AmberLite™ IRC83 ion exchange resins can reduce water hardness and help you achieve up to 30 percent more operating capacity than other weak acid cation resins.

Keep Exploring

Find products for minimal liquid discharge

View our industry-leading minimal liquid discharge products.

Explore other industrial wastewater applications

Our FilmTec™ nanofiltration elements can assist in overcoming the challenges of leachate water treatment, helping to achieve consistent permeate water quality through excellent COD and color removal, while partially removing hardness.

Industrial wastewater has incredible potential as a source of valuable resources. Our nanofiltration elements can help recover salts and minerals while increasing the sustainability and affordability of water recycling systems.

Our industrial wastewater treatment technologies can help treat high chemical oxygen demand (COD), total organic carbon (TOC), total suspended solids (TSS), and total dissolved solids (TDS).

Related resources

See what’s possible

Ask how we can help recover and reuse more wastewater at a lower cost with MLD.