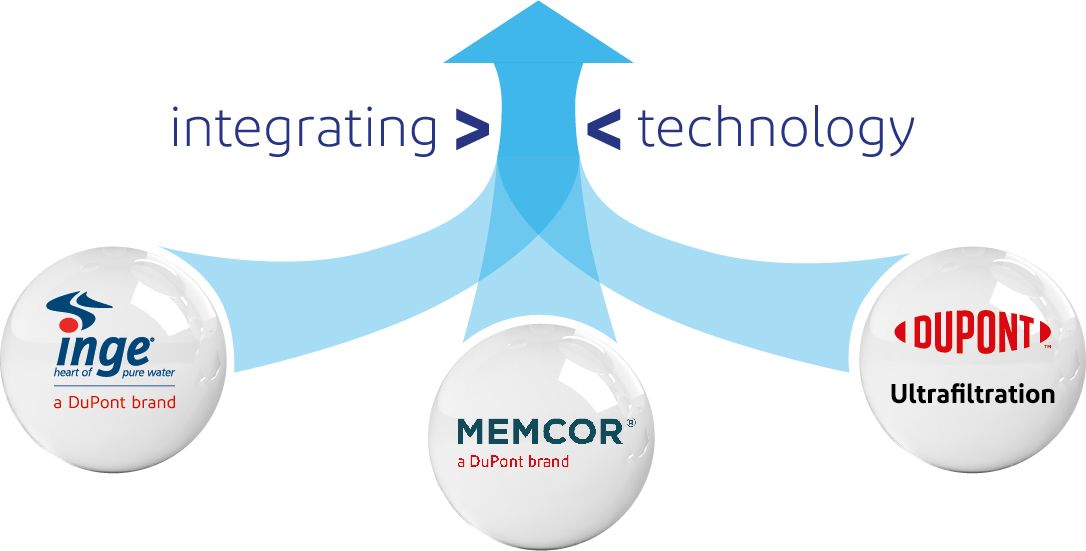

IntegraTec™ Ultrafiltration: a new global leader in Ultrafiltration (UF) Technology

To continue our advancement in the water industry, we are now pleased to launch our new, harmonized UF product portfolio and integrate the brands of heritage DuPont UF, heritage inge® UF, and heritage Memcor® UF under one new, strong brand name – DuPont™ IntegraTec™ Ultrafiltration.

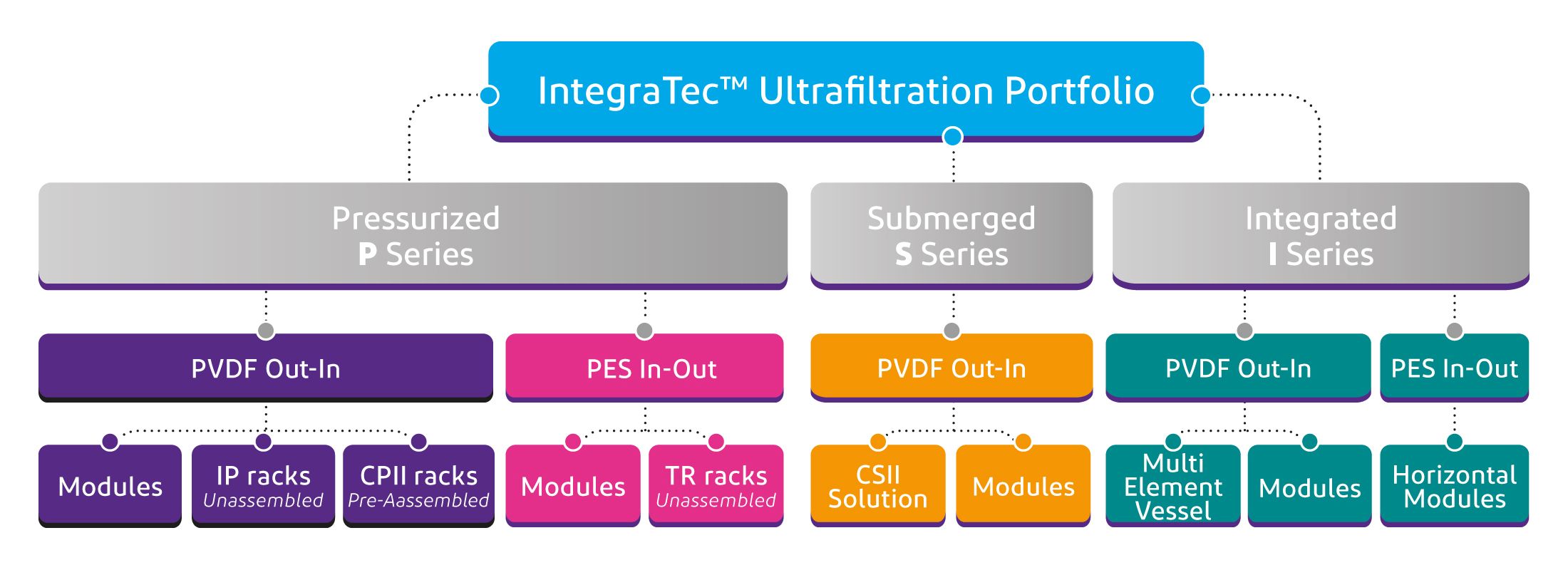

The new IntegraTec™ product line includes the industry proven products that you used in the past as well as new, breakthrough products – all with a new, simplified, and harmonized naming structure.

The IntegraTec™ portfolio of ultrafiltration solutions is built upon 90 years of collective water technology expertise. Comprising trusted products with a proven record of performance when tackling a vast array of filtration challenges, IntegraTec™ helps customers easily harness complementary technologies to build efficient and robust solutions tailored for specific applications.

Our broad portfolio of PES and PVDF membranes enables the IntegraTec™ portfolio to develop the ideal fit to your specific challenge. IntegraTec™ Pressurized, Submerged, and Integrated ultrafiltration module components deliver the solution you need where you need it.

- Pressurized PVDF Out-In

- Pressurized PES In-Out

- Submerged PVDF Out-In

- Integrated PVDF Out-In

- Integrated PES In-Out

Along with offering a one-stop-shop for water technology, boosted by support from a global team of experts, IntegraTec™ emphasizes the benefits afforded by closely integrating ultrafiltration systems with downstream processes. IntegraTec™ is built to provide flexibility and scalability while offering increased efficiency and using advanced manufacturing processes.

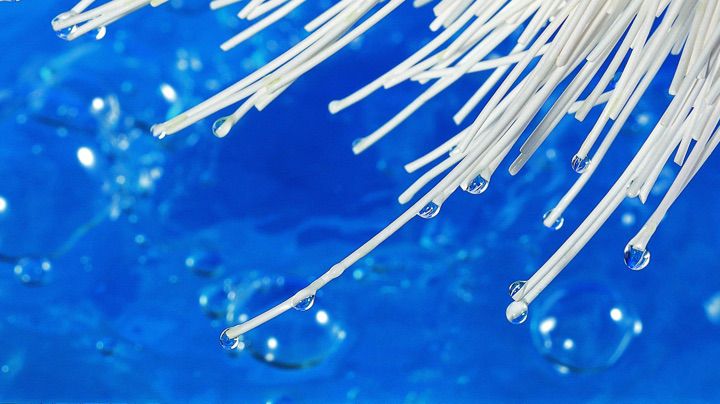

A closer look into integrated ultrafiltration technology

IntegraTec™ PVDF (Polyvinylidene Fluoride) Out-In

Benefits of Pressurized PVDF Out-In include:

- High fouling resistance with hydrophilic formulation

- High oxidation resistance for efficient & cost effective OPEX

- High Recovery through lowest backwash water needs

- Diversity & adaptability through different fiber designs

IntegraTec™ PES (Polyethersulfone) In-Out

Benefits of Pressurized PES In-Out include:

- Low energy with high permeability fiber formulation

- Highest mechanical strength with 7-bore capillary design

- High virus rejection through tight pore size structure

- Diversity & adaptability through different fiber designs

IntegraTec™ PVDF (Polyvinylidene Fluoride) Out-In

Benefits of Submerged PVDF Out-In include:

- Easiest solution to retrofit conventional filter basins

- High solids handling capacity

- Low total cost of ownership with low energy and chemical consumption

- Most compact footprint, especially for large capacity plants

- Single step direct coupling to reverse osmosis (RO)

- Up to 44 modules per rack

- Scalable building blocks to achieve the designed filtration capacity

IntegraTec™ PVDF (Polyvinylidene Fluoride) Out-In Multi-Element Vessels

Benefits of Integrated PVDF Out-In include:

- Outdoor installation with limited civil investment

- Compact footprint

- Quick and simple to maintain

- Scalable and easy to assemble

- Flexible designs to suit various layouts

- High pressure rating FRP vessels

- High water recovery

- Low energy consumption

- Extended engineering and service packages

IntegraTec™ PES (Polyethersulfone) In-Out Integrated Horizontal Modules

Benefits of Integrated PES In-Out include:

- Suitable for retrofits and upgrades

- Various module sizes with high active area

- Durable and robust Multibore® MB and MB PRO fibers

-

Pressurized P Series

IntegraTec™ PVDF (Polyvinylidene Fluoride) Out-In

Benefits of Pressurized PVDF Out-In include:

- High fouling resistance with hydrophilic formulation

- High oxidation resistance for efficient & cost effective OPEX

- High Recovery through lowest backwash water needs

- Diversity & adaptability through different fiber designs

IntegraTec™ PES (Polyethersulfone) In-Out

Benefits of Pressurized PES In-Out include:

- Low energy with high permeability fiber formulation

- Highest mechanical strength with 7-bore capillary design

- High virus rejection through tight pore size structure

- Diversity & adaptability through different fiber designs

-

Submerged S Series

IntegraTec™ PVDF (Polyvinylidene Fluoride) Out-In

Benefits of Submerged PVDF Out-In include:

- Easiest solution to retrofit conventional filter basins

- High solids handling capacity

- Low total cost of ownership with low energy and chemical consumption

- Most compact footprint, especially for large capacity plants

- Single step direct coupling to reverse osmosis (RO)

- Up to 44 modules per rack

- Scalable building blocks to achieve the designed filtration capacity

-

Integrated I Series

IntegraTec™ PVDF (Polyvinylidene Fluoride) Out-In Multi-Element Vessels

Benefits of Integrated PVDF Out-In include:

- Outdoor installation with limited civil investment

- Compact footprint

- Quick and simple to maintain

- Scalable and easy to assemble

- Flexible designs to suit various layouts

- High pressure rating FRP vessels

- High water recovery

- Low energy consumption

- Extended engineering and service packages

IntegraTec™ PES (Polyethersulfone) In-Out Integrated Horizontal Modules

Benefits of Integrated PES In-Out include:

- Suitable for retrofits and upgrades

- Various module sizes with high active area

- Durable and robust Multibore® MB and MB PRO fibers

Find IntegraTec™ ultrafiltration products

View a library of IntegraTec™ product data sheets.

Related technologies

Our technologies provide industry-leading, long-lasting, and cost-effective solutions. Learn more about the technology used in IntegraTec™ products.

UF uses a membrane barrier to exclude colloids, bacteria, and more; for pretreatment in demineralization, industrial water production, drinking water production, or wastewater reuse.

Related industries

Our technologies provide premium solutions for a broad range of industries. The following industries benefit from the IntegraTec™ portfolio of products.

Our technologies and solutions are designed to help you overcome water challenges to produce your desired quantity and quality of industrial utility water.

We develop best-in-class technologies, accompanied by an advanced product portfolio of solutions, to address your crucial wastewater challenges.

We help ensure a steady flow of clean, safe drinking water into local communities with our water-treatment solutions.

We provide high-quality and durable solutions to the seawater reverse osmosis (SWRO) system to last the lifecycle of operations.

We enable the production of some of today’s most popular technologies by facilitating ultrapure water and effective water reuse.

We help energy companies improve operational efficiency with specialized water treatment and wastewater reuse.

We help offices, schools, hospitals, hotels, and universities enhance their facilities with our water-treatment solutions.

We help improve the safety and quality of drinking water in homes with exceptional water treatment.

Related resources

See what’s possible

Ask how we can help your industry or market with our leading IntegraTec™ ultrafiltration portfolio.