Maximizing Efficiency with Minimum Footprint

Article | March 14, 2022

Processing 12.8 million gallons a day, the membrane bioreactor system (MBR) at Star City wastewater treatment plant is one of the largest in the US. Serving the community of Morgantown, West Virginia, the facility also operates a conventional activated sludge process running in parallel with the MBR treatment system, allowing for a real-world side by side comparison of the technologies.

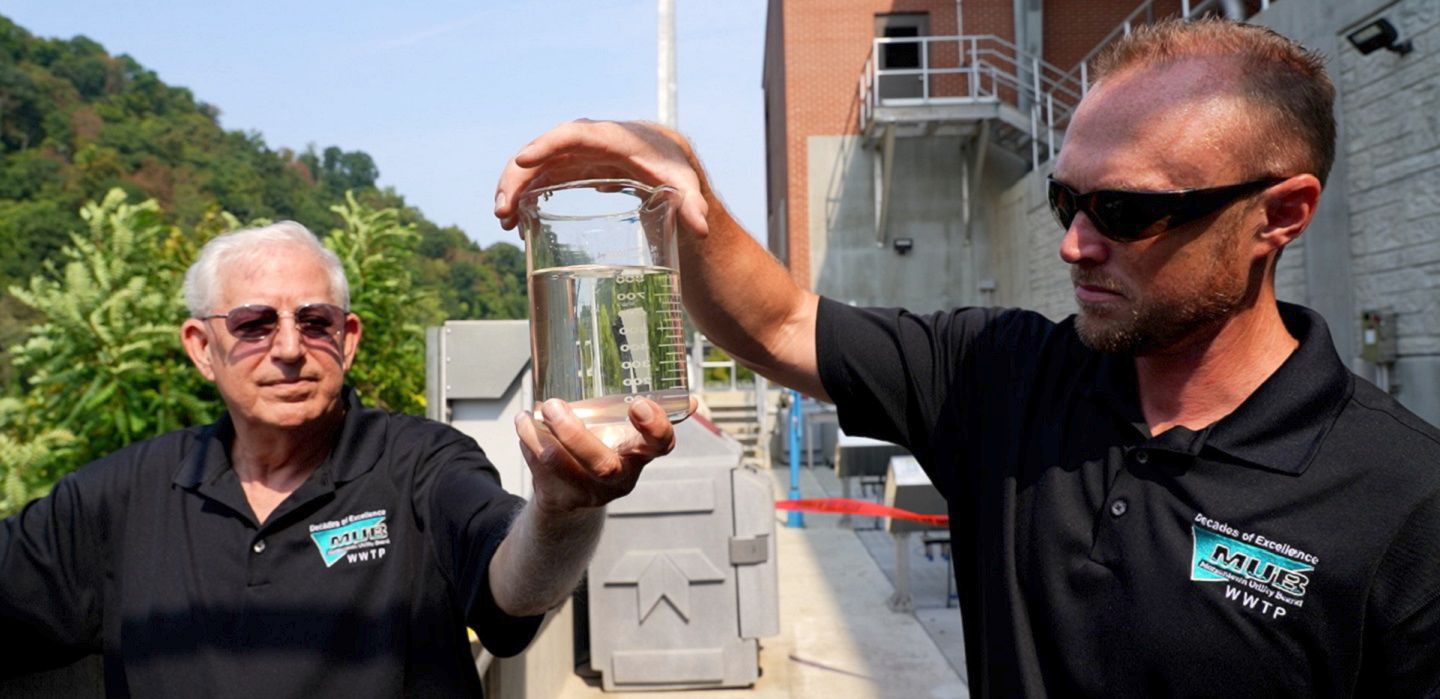

Data collected over a sustained period has shown that the Memcor® MemPulse™ MBR system from DuPont Water Solutions is almost ten times as efficient as the conventional system it runs alongside. The effluent produced by the MBR for discharge into the river is almost indistinguishable from tap water, typically containing less than 1mg per litre of BODs and less than 2mg per litre of TSS. The incredibly high quality of the effluent encouraged the plant to submit an application to the Department for Environmental Protection (DEP) requesting permission for the effluent to bypass the UV disinfection system, providing for additional energy and cost savings.

The MBR system's ability to increase capacity within a small footprint was extremely important with limited space available at the plant to deliver a much-needed capacity upgrade. Placing the membranes in the tank has minimized ongoing operational costs, while the Memcor® MemPulse™ devices connected to each of the membrane modules to provide a dedicated aeration source, ensure optimal performance while reducing energy use and the need for chemicals.

Morgantown Utilities Board were already familiar with MBR technology after it has been installed at the town’s state of the art water treatment plant and quickly identified how it could provide the compact, flexible and adaptable solution they needed.

“We’re kind of familiar with the MBR or membrane technology, having applied that to our water treatment plant,” said Greg Shellito, Manager of Treatment and Production at the Morgantown Utilities Board. “We knew that the MBR system would give a lot of treatment capacity in a very small, short footprint, in the amount of area that we had to build in. And we know that the effluent quality that comes from an MBR system was extremely good.”

In addition to extensive support during the design and deployment phases of the project, the operations team at the plant continue to benefit from round the clock access to expert team members from DuPont Water Solutions. They know they can pick up the phone at 2am and somebody is always ready to provide friendly advice, helping ensure the system runs seamlessly.